At vero eos et odio dignissimos ducimus qui blanditiis praesentium voluptatum

atque corrupti quos dolores et quas molestias excepturi sint.

Make remont ventilation device

If the braking system needs to be vented after replacing the main brake cylinder, brake lines, calipers, rear brake cylinders or anything else, most keymen will use the tried and tested method and do so with a helper. One is in the duck and pumps the liquid through with the brake pedal and the other sits near the vent nipples of the brake lines or caliper. This method also works, but can put an end to the main brake cylinder, since the pedal is never fully kicked in during daily use. This unnatural movement of the main brake cylinder can lead to death, especially if the main brake cylinder has been under the belt for a few years. Besides, you always have to be together.

It's only possible, but I don't want to describe that here. Apart from that, this method does not work at all with a new main brake cylinder, because the main brake cylinder comes without brake fluid and even with a full tank it is almost impossible to get liquid into the main brake cylinder, so there is desperate pedal pedaling and air pumping with minimal brake fluid. Because I work 98.57% alone in my workshop, I came up with something.

One-man operation including main brake cylinder protection. In the magazine Oldtimer-Praxis, issue 6/97, remont airers were presented that actually all work according to the same principle. Enter compressed air into the system by means of a compressor or a fully inflated tyre. However, these devices do not have the right connection for the brake fluid reservoir of the 2CV, I do not have a compressed air connection in my workshop and these things also cost a lot of money. And as a half-seauw, I make my brain work to minimize costs.

So I put together my own machine. Due to the lack of a compressor or permanent compressed air connection, I have thought about where I can get the pressure. I grabbed a perfectly normal bike pump, organized about 2.5m plastic hose and an old cap for the brake fluid reservoir. I put a bicycle quick valve in the bicycle pump and fastened the hose with a hose clamp. I sawed off the floating chamber of the brake fluid reservoir and screwed in a vent nipple of a caliper instead of the float pen.

I attached the other end of the hose to the valve. Now there is another problem. The clogged part of the float cover is not airtight. I visually welded it with the help of a soldering iron. After that, it is very simple: unscrew the cap of the brake fluid reservoir and place the cap of the vent device on top. Then with the bicycle pump back to the rear brake cylinders, nipple open, hose on top with bucket to catch and pump the old brake fluid. It works excellently and you are at the site of the action and can bleed or vent the braking system yourself.

Completely change the brake fluid. When venting the braking system, it should be noted that starting at the furthest removed nipple calculated from the main brake cylinder, so that is one of the rear brake cylinders, right or left of the 2CV that is really irrelevant, I chose the right first, I do not know why, but already had problems when I started on the left. Might have something to do with the direction of rotation of the earth or the yogurt or something...

Then, wisely, at the front of the caliper, to the left of the vent valve, the same method. In the case of drum brakes logically with the two front brake cylinders.

Special tools

When adjusting the rear brake, some caution is required, as slipping with a ring wrench or ratchet with a jammed or round eccentric hexagon ensures that the brake line is in the immediate vicinity and easily damaged. Apart from that, you can no longer adjust the brakes with a round hexagon. The metrinch tools that have been available for some time and that also loosen round nuts or screws are actually almost standard in a well-equipped workshop.

These metrinch tools do not affect the hexagon on the corners, but rather on the flanks because of the waveform, and therefore this tool does not care much about a screwed nut. The disadvantage of the nuts is that they have a rounded shot and that the fairly flat-setting eccentric nuts of the rear brake do not grip well. I sharpened the rounding of a 14 mm metrinch nut so far that the nut has no chance of sliding off, even with a round hexagon.

I did the same with a normal 17-nut. This means that the front axle bolts are tightened when this typical crack occurs when starting and braking. If necessary, press the tool against the screw with a mobile jack to prevent slipping. The roller jack with turntable is perfectly suited for this. Wheel hub puller Special tools are required to remove the wheel hub. It is actually just a thick thorn with the following dimensions:

With this part and a heavy hammer you can knock out the wheel hub. This is necessary if the wheel hub is damaged and needs to be replaced, and especially when replacing the wheel bearings.

Stelmoer spoorstangeind

Special tools are required to adjust or remove the track rod end. Sooner or later, the hammer and screwdriver method will destroy the internal thread of the track rod end and the screw. I made something out of a 1/2' nut. I've bent the nut so that only the holder for the ratchet remains. Then I welded a cross of 3 mm thick metal strips, which fits exactly in the adjusting screw of the rail end. Now you can unscrew the screw or make the adjustment with feeling.

Create carburetor foot key

The carburetor of the 2CV is screwed onto the manifold with four M8 / SW 12 nuts. The rear nuts are easy to reach with a normal ring wrench. This is not the case with the front nuts, which can only be reached with a normal key after removing the oil filling opening. But the oil filling opening can only be loosened with a long T-key SW 11 or a ratchet with extension, apart from the tricky reinstallation.

So the two front nuts are crying out for a special tool. For this I bent a 12 mm ring wrench at right angles in a vice so that about 3 cm from the ring to the bend. Then the end of the fork is deflected and a T-handle is welded from a tube with a diameter of about 1-1.5 cm. This is an excellent way to get to the hidden notes.

I made the same of the forked fork end, because sometimes the ring wrench does not work, because some specialists have tightened the nut with a hammer and chisel, partially smashing the hexagon. It is important that only the nuts SW 12 are used, since the space for the key is already tight. If a nut SW 13 is felted on it for reasons of replacement, one feels really sad when screwing and tightening the nut.

Create steering column puller

The steering column, which must be removed or removed when changing frames, removing front axles or pointing two-spoke steering wheels, usually has a very strong connection to the steering round. To do this, first remove the steering wheel cover and tilt the rust remover in the steering column and let it act. The steering column clamp (SW 11) is best loosened after the Ko-t wing has been removed. Remove the screw and use a screwdriver to pry the clamp open so that it falls down.

Now the locking ring must be removed from the steering lock. To do this, unscrew the cover around the locking ring (SW 7) and unlock the steering lock. Now turn the handlebars and dive into the duck's foot space and look from the back right into the opening of the steering lock. There you can see the locking ring, which is attached with two allen bolts SW 5. Unscrew the screws until the locking ring can be pressed onto the column. It makes sense to remove the flashing light relay, because that's a bit in the way.

Now all that needs to be removed is the steering column. Sometimes it is enough to pull the steering column at the bottom of the steering wheel spoke with more or less powerful handshakes. However, if the steering column is still there with the original rust since 1986, another method should be used. Variants with distribution forks, chisels or screwdrivers at the bottom of the rumdöllern steering column usually lead to their death. If the steering column is already broken or the tooth is turning, it does not matter, but care must be taken that the toothing of the steering round is not crumbled if it is not already over...

If the steering column is to survive, a tractor must be used. My construction for this looks like this: Take an old handlebar and remove the foam rubber in the middle, where it is screwed onto the steering column. Now bend this centre piece loose and read an M 12 nut on the top. Make sure that the nut is exactly flat on the middle part. The nut must then be machined with the flex so that all three screws of the steering wheel attachment can be screwed onto the steering column. If necessary, work with allen bolts.

Now turn an M 12 wire rod, which is about 50 mm longer than the steering column, through the welded nut and weld another nut to it. To pull off the steering column, remove the handlebar, insert the trigger into the steering column and secure it with the three SW 11 screws. Now turn the wire rod into the steering column with a 19 mm spanner until it gets to the steering round of the front axle. As you continue to rotate, the steering column is now carefully pulled through the curve. Voila!

Before mounting the steering column, check that the tooth is still in order, that the steering column has a crack (usually at the level of the cutout for the steering column screw) or is even bent. When replacing, do not forget the locking ring, the cover of the ignition lock and the rubber on the pedal base. It is best to replace the steering column clamp. When driving in the steering column, it is best to work together. The pillar is slowly lowered from the inside, the second holds the clamp around the pillar and slowly steers the steering column into place. The cutout of the curve should be exactly in line with that of the steering column, otherwise you will be sad when trying to mount the screw. Very important: always use a new screw (size M7 x 50 mm), self-locking nut and rings 7x14!

The position of the steering wheel spoke must of course also be taken into account when mounting. With the single spoke steering wheel, the spoke is logically nicely parallel at eight o'clock, with two-spoke steering wheels. After sliding the steering column open on two-spoke steering wheels, do not screw everything together, but check the middle position of the steering wheel by briefly and carefully driving in a straight line and possibly shifting the steering column again. Precise alignment greatly increases the entertainment value of a two-spoke handlebar.

Make brake drum puller

Tractors for the rear brake drums are expensive and if you don't screw on a 2CV every week you may only need it every few years. The alternative to this is as simple as it is ingenious. You need an old rim, a approx. 20 cm long M 12 wire rod and a pair of M 12 nuts. A nut is screwed into the middle of the wire rod and inserted into the hole in the middle of the rim. Then put a second nut on it from the other side and align the wire rod so that it passes vertically and tighten the nut.

Now the nut on the inside of the rim is welded. The nut on the outside now comes to the end of the wire rod and is also welded, the same happens at the other end of the wire rod. If we now want to pull off the brake drum, we can leave this work to a toddler, since Armold-Schwarzenegger forces and the like are not necessary. A little fat on the inner nut is just as useful as reversing the eccentric (who hasn't forgotten?).

Even brakes with clogged cylinders and fixed brake shoes after a long period of downtime are no longer an issue, but the brake shoes are bent and the plates with the locking springs jump through, but such brakes need to be completely replaced anyway. To pull off the brake drum, screw the wire rod into the rim of the trigger, then screw the wheel nuts onto the drum, screw the wire rod into it, press it onto the astap and the rim pulls the drum off with gentle force. Pulling the drum with the screwed wheel is not recommended, as this allows the wheel bearing to jump.

Chassis numbers and years of construction

Below are the years of construction and chassis numbers (VIN) of the 2CV:

| Year | Type | wine |

| 1949 | 2CV A | 1 - 924 |

| 1950 | 2CV A | 925 - 7100 |

| 1951 | 2CV A | 7101 - 21850 |

| 2CV AT | 3000000 - 301700 | |

| 1952 | 2CV A | 21851 - 43150 |

| 2CV AT | 301701 - 309450 | |

| 1953 | 2CV A | 43151 - 77950 |

| 2 CV AT | 309451 - 322500 | |

| 1954 | 2CV A | 77951 - 121200 |

| 2CV AT | 322501 - 338450 | |

| 1955 | 2CV A | 121201 - 124500 |

| 2CV AZ | 150001 - 210188 | |

| 2CV AT | 338301 - 338450 | |

| 2CV AZU | 450001 - 470552 | |

| 1956 | 2CV A | 124501 - 125315 |

| 2CV AZ | 210189 - 297458 | |

| 2CV AT | 338451 - | |

| 2CV AZU | 470553 - 491184 | |

| 1957 | 2CV A | 125316 - 125372 |

| 2CV AZ | 297459 - 395334 | |

| 2CV AZU | 491185 - 519882 | |

| 1958 | 2CV A | 125373 - 125451 |

| 2CV AZ | 395335 - 478000 | |

| 2CV AZ | 1000001 - 1030214 | |

| 2CV AZL | 2000001 - 2001706 | |

| 2CV Sahara | ||

| 2CV AZU | 519823 - 551967 | |

| 1959 | 2CV A | 125452 - 125539 |

| 2CV AZ | 1030215 - | |

| 2CV AZ | 2350001 - 2352809 | |

| 2CV AZL | 2001701 - 2250554 | |

| 2CV Sahara | ||

| 2CV AZU | 551968 -589860 | |

| 1960 | 2CV A | 125540 - 125570 |

| 2CV AZ | 2352810 - 2472482 | |

| 2CV AZL | 2250545 - 2265599 | |

| 2CV Sahara | ||

| 2CV AZU | 589860 - 636247 | |

| 1961 | 2CV A | 125571 - 128685 |

| 2CV AZ | 2472483 - 2500399 | |

| 2CV AZL | 2265600 - 2285436 | |

| 2CV AZLP | 2510001 - 2591863 | |

| 2800001 - 2801039 | ||

| 2CV Sahara | 000001 - 000199 | |

| 2CV AZU (old bonnet) | 636248 - 680000 | |

| 2CV AZU (new bonnet) | 680001 - 682408 | |

| 1962 | 2CV AZ | 2285437 - 2287173 |

| 2CV AZL | 2591864 - 2600508 | |

| 2CV AZLP | 2801040 - 2801252 | |

| 2CV 15hp | 8294001 - 8297422 | |

| 2CV 15hp centrifugaal | 8310001 - 8497422 | |

| 2CV Sahara | 000200 - 000449 | |

| 2CV AZU | 682409 - 741016 | |

| 1963 | 2CV AZ | 8297629 - 8299500 |

| 2CV AZL | 8497423 - 8561105 | |

| 2CV AZA / AZAM | 1350001 - 1434390 | |

| 2CV Sahara | 000501 - 000618 | |

| 2CV AZU | 741017 - 761026 | |

| 2CV AZU 2 / 63 > | 1140001 - 1150957 | |

| 1964 | 2CV AZ | 8561201 - 8561291 |

| 2 CV AZAM | 1350001 - 1439999 | |

| 1460001 - 1462476 | ||

| 2CV AZL ENAC | 1440001 - 1454521 | |

| 1456001 - 1475903 | ||

| 2CV AZAM Luxe | 1490001 - 1559464 | |

| 1595001 - 1595316 | ||

| 2CV AZL | 1560001 - 1589919 | |

| 2CV Sahara | 000631 - 000707 | |

| 2CV AZU | 1151001 - 1167613 | |

| 2CV AZU 6 / 64 > | 1168001 - 1169670 | |

| 1965 | 2CV AZ | 8561300 - 8561522 |

| 8561500 - 8561522 | ||

| 2CV AZL | 1600001 - 1603541 | |

| 1635001 - 1635471 | ||

| 2CV AZL A | 1635001 - 1635471 | |

| 1640001 - 1647847 | ||

| 1732001 - 1746460 | ||

| 2CV AZAM | 1620000 - 1628440 | |

| 1675001 - 1677121 | ||

| 1690001 - 1711184 | ||

| 1712000 - 1720305 | ||

| 1755001 - 1806610 | ||

| 2CV Sahara | 000710 - 000742 | |

| 2CV AZU | 1170001 - 1171184 | |

| 1175001 - 1180300 | ||

| 1966 | 2CV AZ | 8561601 - 8561626 |

| 2CV AZL | 1825000 - 1834310 | |

| 2CV AZL | 1840000 - 1859446 | |

| 1861001 - 1862315 | ||

| 2CV AZAM | 1810001 - 1824696 | |

| 1865000 - 1954001 | ||

| 2CV Sahara | 000750 - 000779 | |

| 1967 | 2CV AZ | 8561630 - 8561655 |

| 2CV AZL | 7000000 - 7007201 | |

| 7009000 - 7009299 | ||

| 2CV AZL A (AZA) | 7028000 - 7042477 | |

| 7046000 - 7046624 | ||

| 2CV AZAM | 7012000 - 7021960 | |

| 7055000 - 7095346 | ||

| 2CV AZAM Export | 7022101 - 7024784 | |

| 7095601 - 7112929 | ||

| 2CV Sahara | 000780 - 000791 | |

| 2CV AZU | 1196100 - 1205613 | |

| 1968 | 2CV AZA | 7167000 - 7196400 |

| 2CV AZU | 7117001 - 7125499 | |

| 1969 | 2CV AZA | 7197000 - 7234616 |

| 2CV AZU | 7125700 - 7137141 | |

| 2CV AK 33hp | 9174300 - 9189999 | |

| 2CV AK | 9159000 - 9199000 | |

| 1970 | 2CV AZA | 7235001 - 7270050 |

| 2CV 4 AZA 2 | 7850001 - 7886311 | |

| 2CV 6 AZKA | AZKA0000KA0002 - AZKA0001KA1952 | |

| 2CV AK | 9528701 - | |

| 1971 | 2CV 4 | 7888001 - 7954193 |

| 2CV 6 | AZKA0001AK4001 - AZKA0004KA8654 | |

| 2CV Sahara | ||

| AZU | 7147501 - | |

| AKS | 00AK0002 - | |

| 1972 | 2CV 4 | 7960001 - |

| 2CV 6 | AZKA0005KA2001 - | |

| AZU | 7156501 - 7160119 | |

| AZU A | 7712001 - 7714563 | |

| AKS | 02AK7001 - 7714563 | |

| 1973 | 2CV 4 | 9066001 - |

| 2CV 6 | AZKA0010KA5001 - | |

| AZU | 7815001 - | |

| AKS | 05KA5001 - | |

| 1974 | 2CV 4 | 9066001 - |

| 2CV 6 | AZKA0015KA6501 - | |

| AZU B | 0782501 - | |

| AKS | 05KA5001 - | |

| 1975 | 2CV 4 | 09140001 - |

| 2CV 6 | AZKA0023KA8001 - | |

| AZU B | 07837001 - | |

| AKS | 12AK7001 - | |

| 1976 | 2CV 4 | 00KB0001 - |

| 2CV 4 Spot | 03KB5635 - | |

| 2CV 6 | AZKA0030KA9001 - | |

| AZU | 00AP0001 - | |

| AKS | 15AK2001 - | |

| 1977 | 2CV 4 | 06KB0001 - |

| 2CV 6 | AZKA0038KA0001 - | |

| AZU | 01AP0001 - | |

| AKS | 18AK0001 - | |

| 1978 | 2CV 4 | 06KB0001 - |

| 2CV 6 | AZKA0044KA5001 - | |

| AZU | 01 AP 6001 - | |

| AKS | 20AK6001 - | |

| 1979 | 2CV Special | 18KB6001 - |

| 2CV 6 | AZKA0050KA5001 - | |

| 1980 | 2CV 6 | AZKA0056KA4001 - |

| 1981 | 2CV 6 | AZKA0068KA0001 - |

| 1982 | 2CV 6 | AZKA0077KA5001- |

| 1983 | 2CV 6 | AZKA0088KA2001 - |

| 1984 | 2CV 6 | AZKA0096KA6001 - |

| 1985 | 2CV 6 | AZKA00KA038501 - |

| 1986 | 2CV 6 | AZKA00KA110001 - |

| 1987 | 2CV 6 | AZKA00KA192501 - |

| 1988 | 2CV 6 | AZKA00KA296001 - |

| 1988 | 2CV 6 Production end F | AZKA00KA302493 (25.2.88 / 4127) |

| 1990 | 2CV 6 Production end P | AZKA00KA376002 (27.9.90 / 5010) |

Of course we have also listed them for the Dyane and Acadyane:

| Year | Type | wine |

| 1968 | Dyane AYA-A | 7277000 - 7293431 |

| Dyane AYA-AM | 7307000 - 7359448 | |

| Dyane AYA3-A | 7500000 - 7517466 | |

| Dyane AYA3-AM | 7530000 - 7577540 | |

| Dyane AYA2-A | 7362000 - 7370211 | |

| Dyane AYA2-AM | 7372000 - 7382436 | |

| 1969 | Dyane AYA-A | 7294000 - 7294533 |

| Dyane AYA-AM | 7359800 - | |

| Dyane AYA3-A | 7586000 - 7587327 | |

| Dyane AYA3-AM | 7587000 - 7583509 | |

| Dyane AYA2-A | 7385000 - 7389996 | |

| 7400000 - 7415100 | ||

| Dyane AYA2-AM | 7390000 - 7393340 | |

| Dyane AYB-A | 7590002 - 7607878 | |

| Dyane AYB-AM | 7620001 - 7658122 | |

| 1970 | Dyane 4 AYA2-A | 7418002 - 7458855 |

| Dyane AYB-A | 7665002 - 7711631 | |

| Dyane AYB-AM | 7690001 - | |

| Dyane 6AY-CB | 00CB0002 - 03CB7982 | |

| 1971 | Dyane 4 AYA2-A | 7460001 - 7498460 |

| Dyane 6AY-CB | 03CB8001 - 08CB9261 | |

| 1972 | Dyane 4 AYA2-A | 7715001 - 7751818 |

| Dyane 6AY-CB | 09CB2501 - 14CB9372 | |

| 1973 | Dyane 4 AYA2-A | 7754001 - 7769762 |

| Dyane 6AY-CB | 15CB2001 - 21CB5669 | |

| 1974 | Dyane 4 AYA2-A | 7770001 - 7790300 |

| Dyane 6AY-CB | 21CB6001 - 28CB6130 | |

| 1975 | Dyane 4 AYA2-A | 7793001 - |

| Dyane 6AY-CB | 30CB0001 - 37CB4000 | |

| 1976 | Dyane 6 | 37CB4001 - |

| 1977 | Dyane 6 | 47CB0001 - |

| 1978 | Dyane 6 | 54CB5001 - |

| 1979 | Dyane 6 | 61CB6001 - |

| 1980 | Dyane 6 | 67CD2001 - |

| Acadiane | 04CD0001 - | |

| 1981 | Dyane 6 | 74CB0001 - |

| Acadiane | 06CD8101 - | |

| 1982 | Dyane 6 | 78CB0001 - |

| Acadiane | 10CD0001 - | |

| 1983 | Dyane 6 | 82CB4001 - |

| Acadiane | 13CD2001 - | |

| 1984 | Acadiane | 15CD3001 - |

| 1985 | Acadiane | 17CD0001 - |

| 1986 | Acadiane | 20CD0001 - |

| 1987 | Acadiane | 21CD2001 - |

| 1988 | Acadiane | 22CD2001 - |

From the Ami we also have them:

| Year | Type | wine |

| 1961 | Friend 6 | 009001 - 014521 |

| 1962 | Friend 6 | 014522 - 044766 |

| 100102 - 227999 | ||

| 1963 | Friend 6 | 044767 - 055630 |

| 044767 - 055630 | ||

| 129000 - 199999 | ||

| 9200001 - 9209971 | ||

| 1964 | Friend 6 | 9215001 - 9246157 |

| 9250001 - 9333602 | ||

| 1965 | Friend 6 Sedan | 9334000 - 9392303 |

| 9393500 - 9394564 | ||

| Friend 6 Break | 9100001 - 9101399 | |

| 9123000 - 9136783 | ||

| 9102000 - 9119999 | ||

| 9600000 - 9646041 | ||

| 1966 | Friend 6 Sedan | 9415000 - 9432980 |

| 9435000 - 9437535 | ||

| 9395000 - 9410659 | ||

| 9438000 - 9442255 | ||

| Friend 6 Break | 9136800 - 9149166 | |

| 9646100 - 9762048 | ||

| 1967 | Friend 6 Sedan | 9443000 - 9438966 |

| 9460000 - 948???? | ||

| Friend 6 Break | 9763000 - 9770664 | |

| 9778000 - 9898718 | ||

| 1968 | Friend 6 Sedan | 28 PS 9484000 - 9521395 |

| 35 PS 370000 - 374154 | ||

| Friend 6 Break | 28 HP 4 - Seater 9905000 - 9908240 | |

| 35 HP 4 - Seater 520000 - 520806 | ||

| 28 HP 5 - Seater 9920000 - 9974228 | ||

| 35 HP 5 - Seater 524000 - 534285 | ||

| 28 PS Club 200000 - 219564 | ||

| 35 PS Club 230000 - 236344 | ||

| 1969 | Friend 6 Sedan | 375500 - 390857 |

| Friend 6 Break | 4 - Seater 537000 - 538563 | |

| 5 - Seater 549000 - 601388 | ||

| Club 237000 - ? | ||

| Friend 6 Service / Business | 393 000 - 429 999 | |

| Friend 8 Sedan | 435 000 - 447 927 | |

| 1971 | Friend 8 | Sedan 17JA0001 - ? |

| Break 14JB5001 - ? | ||

| Service 01JC2001 - ? | ||

| Super Friend | Sedan 00JF0001 - ? | |

| Break 00JG0001 - ? | ||

| Service 00JH0001 - ? | ||

| 1974 | Friend 8 | Sedan 19JA5501 - ? |

| Break 17JB4501 - ? | ||

| Service 01JC5501 | ||

| 1975 | Friend 8 | Sedan 22JA1001 - ? |

| Break 20JB5001 - ? | ||

| Service 01JC8501 - ? | ||

| 1976 | Friend 8 | Sedan 23jA9501 - ? |

| Break 22JB7001 - ? | ||

| Service 02JC1701 - ? | ||

| 1977 | Friend 8 | Sedan 26JA0001 - ? |

| Service / Company 02JC6001 - ? | ||

| Break 26JB0001 | ||

| 1978 | Friend 8 | Sedan 27JA1001 - ? |

| Break 27JB8501 | ||

| Company 02JC8501 - ? |

And finally, an overview of the Mehari:

| Year | Type | wine |

| 1968 | Mehari | |

| 1969 | Mehari | 9 169 300 - 9 999 999 |

| 1970 | Mehari | 00CA1901 - 01CA3028 |

| 1971 | Mehari | 01CA3028 - 02CA4500 |

| >1972 | Mehari | 02CA4501 - 03CA5000 |

| 1973 | Mehari | 03CA5001 - 04CA6000 |

| 1974 | Mehari | 04CA6001 - 06CA1001 |

| 1975 | Mehari | 06CA1001 - 06CA9999 |

| 1976 | Mehari | 07CA0001 - 07CA9999 |

| 1977 | Mehari | 08CA0001 - 08CA9999 |

| 1978 | Mehari | 09CA0001 - 09CA8000 |

| 1979 | Mehari | 09CA8001 - 10CA4000 |

| Mehari 4x4 | 00CE0001 - 00CE1000 | |

| 1980 | Mehari | 10CA4001 - 11CA0500 |

| Mehari 4x4 | 00CE1001 - 00CE2000 | |

| 1981 | Mehari | 11CA0501 - 11CA9999 |

| Mehari 4x4 | 00CE2001 - 00CE4000 | |

| 1982 | Mehari | 12CA0001 - 12CA7000 |

| Mehari 4x4 | 00CE4001 - 00CE5000 | |

| 1983 | Mehari | 12CA7001 - 13CA3000 |

| Mehari 4x4 | 00CE5001 - | |

| 1984 | Mehari | 13CA3001 - 14CA1000 |

| 1985 | Mehari | 14CA1001 - 14CA9999 |

| 1986 | Mehari | 15CA0001 - 15CA3000 |

| 1987 | Mehari | 15CA3001 - |

The difference in tire size

Which tyre should you choose for your 2CV?

There are many opinions and just as many opinions on this.

Let's start with the basics, what is the difference in the commonly used tire size 125/80R15 and 135/80R15?

| 125/80R15 | 135/80R15 | difference | |

| Diameter in mm | 581 | 597 | 16 = 2.8% |

| Width in mm | 125 | 135 | 10 = 8% |

| Afwenteling in mm | 1825.27 | 1875.53 | 50.27 = 2.8% |

| Cheek height in mm | 100 | 108 | 8 = 8% |

| Number of rotations per km | 547.86 | 533.18 | -14.68 = -2.7% |

Tires crossed and placed side by side. The facts in a row: the height difference between the tyres is only 16mm and a tyre of 135/80R15 could in theory last longer, because the tyre makes fewer revolutions per kilometre driven.

What we do have to take into account is the deviation between the actual speed and the speed indicated by the speedometer (although it is also not calibrated.) when we change the tyre size to 135/80R15:

| Snelheidsmeterverschil | |

| Speedometer read | Actual speed |

| 30 km/h | 30.83 km/h |

| 40 km/h | 41.11 km/h |

| 50 km/h | 51.38 km/h |

| 60 km/h | 61.66 km/h |

| 70 km/h | 71.93 km/h |

| 80 km/h | 82.21 km/h |

| 90 km/h | 92.48 km/h |

| 100 km/h | 102.76 km/h |

| 110 km/h | 113.58 km/h |

| 120 km/h) | 123.3 km/h |

| 130 km/h) | 133.58 km/h |

Kleurtabel 2CV

Motor

Motor

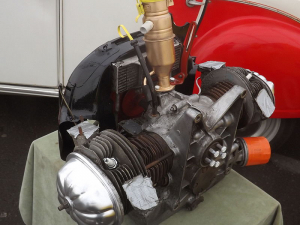

All 2CV and derivatives have an air-cooled twin-cylinder boxer engine with central camshaft and 2 valves per cylinder. All engines can run smoothly on unleaded fuel. Any lead additives are not required. The preparation of the mixture is always done with a carburetor. Injection or catalysts never came out of the factory.

On the nameplate attached to the top of the engine, you can easily see which engine it is.